2026 ERP Trends That Will Reshape Manufacturing

What if your ERP could anticipate machine failures, optimize inventory in real time, and adapt instantly to supply chain disruptions? In 2026, that...

5 min read

David Warford Sr. : November 6, 2025

Manufacturing IT leaders are under increasing pressure. Your traditional Enterprise Resource Planning (ERP) systems are excellent at recording what happened—tracking inventory, logging work orders, and managing financials. The problem is they are almost entirely reactive. In today's volatile market, this data lag creates inefficiency, unplanned downtime, and waste.

The conversation has now shifted from whether AI can help to how it integrates. Integrating artificial intelligence directly into the manufacturing ERP system is no longer a futuristic concept; it's the central strategy for achieving genuine smart manufacturing. This article explores how this AI integration works, focusing on the transformative power of predictive analytics and intelligent automation.

An AI model is only as good as the data it’s fed. A manufacturing ERP system is the organization's central nervous system, holding the master data for production, inventory, finance, and supply chains. By integrating AI with this existing ERP platform, you provide the "brain" (AI) with a complete, contextualized view of the entire operation, turning siloed data into actionable intelligence.

Traditional ERP systems excel at data collection. An AI-powered ERP goes further by using this data for analysis. For example, an AI algorithm needs data from ERP modules for procurement (supplier lead times), production (machine uptime), and finance (cost of downtime) to build an accurate predictive maintenance model. Without the ERP centralizing this, AI tools would be sampling incomplete, often conflicting data from legacy systems. This synergy ensures AI-driven insights are based on a comprehensive, validated business reality, not just isolated shop floor systems.

Smart manufacturing hinges on bridging the gap between operational technology (OT) from sensors and shop floor machines, and information technology (IT) managed by the ERP. Modern ERP solutions with integrated AI capabilities act as this bridge. They ingest real-time OT data (like temperature or vibration) and contextualize it against IT data (like maintenance schedules or work orders). This allows AI algorithms to spot correlations a human would miss, such as a specific raw material batch (IT data) correlating with micro-stoppages on a specific machine (OT data).

Integrating AI into modern ERP systems isn't just an upgrade; it fundamentally changes core manufacturing workflows. The benefits move beyond simple reporting to active, intelligent intervention. This transformation is most profound in areas that directly impact cost, quality, and throughput: predictive analytics and intelligent automation.

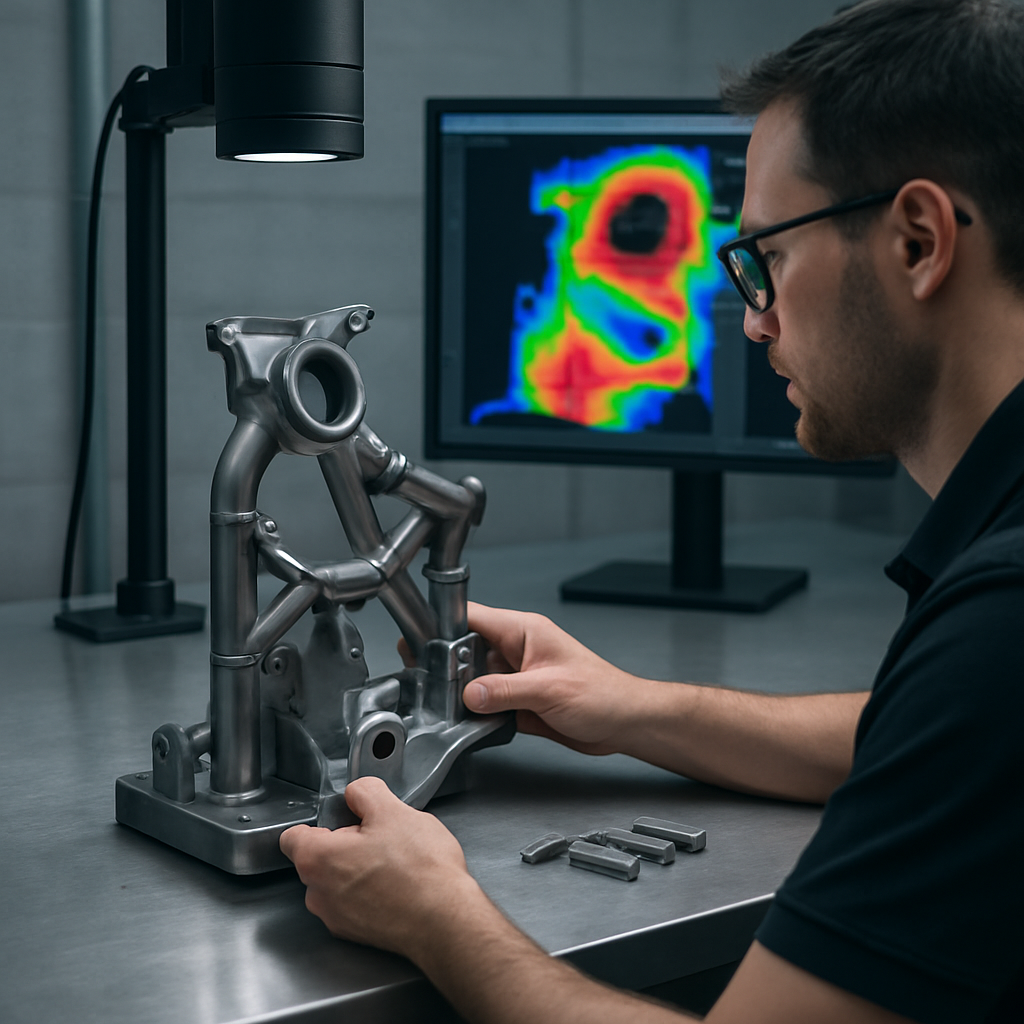

Traditional manufacturing runs on preventative maintenance (fixed schedules) or reactive maintenance (fixing what's broken). An AI-powered ERP introduces predictive maintenance. AI algorithms analyze sensor data and historical maintenance records within the ERP, identifying subtle patterns that precede a failure. Instead of just flagging an error, the system can automatically generate a maintenance work order in the ERP, check inventory for the required spare parts, and even schedule the downtime to minimize production disruption. This shift alone can reduce equipment downtime by up to 50%, according to insights from McKinsey.

AI-driven automation within the ERP streamlines complex manufacturing processes that were previously manual. Consider quality control: AI-powered computer vision systems can inspect products on the assembly line with greater speed and accuracy than human inspectors. When a defect is found, the system doesn't just stop the line; it logs the defect type, quantity, and associated work order directly into the ERP's quality module. This triggers real-time alerts and provides a clean data set for root cause analysis, linking defects back to specific material batches or machine settings.

Most manufacturing companies struggle with the bullwhip effect in their supply chains. AI in ERP systems dramatically improves demand forecasting by analyzing vast, complex datasets beyond just historical sales. The AI-enabled ERP can incorporate external factors like weather patterns, logistics delays, social media trends, and commodity price fluctuations to create a highly accurate, dynamic forecast. This allows the ERP to automatically adjust production schedules and procurement orders, optimizing inventory levels to prevent both stockouts and costly overstocking.

Embracing the transformative power of AI requires a clear strategy, not a "big bang" implementation. For IT leaders, this means preparing the technical and data foundation before deploying AI applications. A phased approach ensures that each step delivers measurable value and builds momentum for wider AI adoption.

You cannot build smart manufacturing on a foundation of "dirty" data. The first step is a comprehensive assessment of your data hygiene, governance, and accessibility within your current ERP system. This involves identifying critical data sources, cleansing inaccuracies, and standardizing formats across different manufacturing sites or legacy systems. An AI Readiness Assessment is crucial to map your existing data architecture and identify gaps that must be closed before AI algorithms can be trusted to make automated decisions.

IT leaders must decide how AI will connect to the ERP. Many modern ERP vendors are now embedding AI capabilities directly into their core modules, offering pre-built solutions for common tasks. Alternatively, you can use a separate AI platform (e.g., from a major cloud provider) and integrate it with your ERP via APIs. Embedded AI is often faster to deploy for specific use cases, while a platform approach offers more flexibility to build custom, proprietary AI applications. The right choice depends on your team's skills, the flexibility of your cloud ERP systems, and your long-term strategic goals.

Avoid trying to boil the ocean. Start your AI integration with a single, high-impact pilot project that has a clear, measurable KPI—for example, reducing downtime on a single critical assembly line using predictive maintenance. This pilot serves as a proof-of-concept, helping you refine your integration process, build trust with operations teams, and demonstrate tangible ROI. Research from Gartner reinforces this minimum viable product (MVP) approach, proving that iterative development is key to scaling complex tech.

The synergy between AI and ERP is already delivering significant results across the manufacturing sector. These practical applications demonstrate how integrating intelligence into the core system solves specific, costly problems.

An automotive parts supplier was experiencing high defect rates on a complex welding line, leading to costly rework. By integrating AI-powered computer vision with their manufacturing ERP system, they moved quality inspection in-line. The AI now analyzes high-resolution images of each weld in real-time, catching microscopic flaws. Crucially, this defect data is fed back to the ERP, which correlates it with machine settings, operator ID, and raw material batches, enabling engineers to identify and fix the root cause of defects 10x faster.

A large consumer packaged goods (CPG) company used its AI-enabled ERP to automate its warehouse logistics. The ERP's demand forecast, now powered by AI, automatically generates replenishment orders. This information is sent directly to autonomous mobile robots (AMRs) on the warehouse floor. The AMRs pick, pack, and prepare orders for shipment, with the ERP's inventory module updated instantly. This automation reduced picking errors by over 90% and allowed the company to reallocate 60% of its warehouse staff to more value-added roles.

The integration of AI and ERP is not the end goal; it's the foundation for the next wave of transformation. As of 2025, Generative AI is beginning to move from consumer applications into the industrial space. This presents a new frontier for smart manufacturing, where AI doesn't just analyze data but actively collaborates with users.

The AI revolution is transforming ERP by changing how users interact with complex data. Soon, a plant manager won't need to run a complex report to understand a production shortfall. They will simply ask the generative AI interface, "Why did Line 3's output drop by 15% yesterday?" The AI will query the ERP, analyze machine sensor data, check maintenance logs, and respond in plain English: "Line 3's output dropped because of a 45-minute stoppage at 2:30 PM, caused by a bearing failure (Part #45B) that was flagged by the predictive maintenance module 72 hours prior."

Generative AI can also be used for "digital twin" simulations and optimization. A modern ERP system holds the bill of materials (BOMs) and production routings. A generative AI can run thousands of "what-if" scenarios, suggesting new production schedules to optimize for energy costs, or even recommending minor changes to a product's BOM based on real-time supply chain disruptions. According to Deloitte, this ability for AI to co-create and simulate solutions will be a major driver of competitive advantage for manufacturing companies.

Integrating AI with your ERP is the key to unlocking true smart manufacturing, moving your operations from reactive to predictive. This journey transforms your manufacturing ERP system from a simple record-keeper into an intelligent engine for automation and optimization.

The transformative power of AI is already here, but it requires a strategic approach to data, integration, and implementation. If you are a manufacturing leader looking to harness the power of AI-powered ERP, the first step is a clear strategy.

Contact us to explore AI-ERP integration solutions and develop your AI strategy.

What if your ERP could anticipate machine failures, optimize inventory in real time, and adapt instantly to supply chain disruptions? In 2026, that...

6 min read

The push for digital transformation in manufacturing is relentless. Executives face constant pressure to increase efficiency, build resilient supply...

Manufacturing success relies on more than just efficient production lines—it demands a fully integrated approach to managing all business operations....